The sewing industry is embracing innovative technologies that are revolutionizing the way garments are produced. Two noteworthy advancements are digital pattern projection and robotics, both of which promise to enhance efficiency, precision, and customization.

One of the most exciting innovations is Ditto™—a breakthrough digital pattern projection system developed by JOANN and SINGER®. This technology allows sewists to project customizable patterns directly onto fabric, eliminating the need for paper patterns. It offers real-time adjustments to fit specific body measurements, making the process faster and more precise. Ditto simplifies setup, and its ability to adjust designs—like modifying necklines or sleeve lengths—is a game changer for both amateur and professional sewists. This technology also promotes sustainability by reducing paper waste

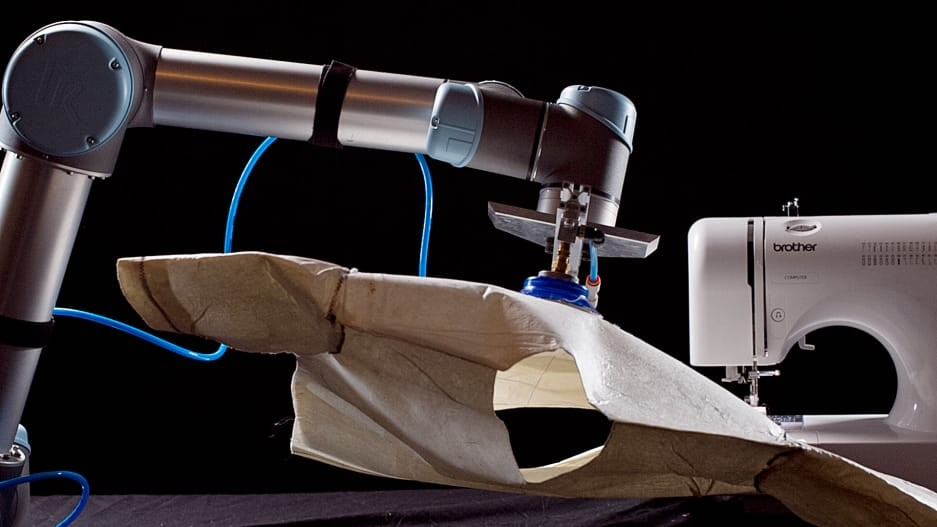

On the industrial side, robotics is gaining momentum in sewing operations. Robotic sewing systems equipped with advanced machine vision can detect fabric misalignments and adjust accordingly. This technology is particularly useful for handling delicate fabrics that require fine adjustments, such as in apparel manufacturing, automotive, and even aerospace industries. Robots designed for sewing are highly specialized, with some systems using multi-arm or dual-arm configurations to increase precision and throughput

. These robots not only improve efficiency by reducing waste and downtime but also ensure high-quality stitching with fewer errors.

These advancements mark a significant shift in the sewing industry, where both hobbyists and manufacturers can look forward to more innovative, accurate, and environmentally friendly methods of fabric manipulation. The future of sewing is increasingly digital and automated, setting the stage for even more exciting developments to come.